Copyright © 2024, Jason T. Jacques

Last updated 2024-09-21

When a suggested YouTube video about the Science Fair Microcomputer Trainer caught my eye, I could never have anticipated the rabbit hole that I was about to stumble into.

This document offers a long read into my involvement in Michael Wessel's endeavours to acquire and understand the ROM code of the Busch Microtronic 2090. It is not a tutorial, but rather my recollection and reflections. At each juncture I provide copious references and delve into the background and history of the development or discovery, taking the opportunity to disclose some hopefully interesting titbit or aside. Despite its length, it is almost certainly incomplete. Nevertheless, to aid the more focused reader, this text is split into several sections. As far as possible each section stands alone.

In February 2024 Michael Wessel uploaded the latest video in his series offering a brief overview and profile of some early vintage educational computer systems. In his video, it appeared that Michael had relied on one of the unreferenced sources that misreport the launch date of the Microcomputer Trainer as 1976. While the TMS1100 may have been initially released in 1976, the Science Fair kit had, in fact, been listed as new for '85 on page 155 of the 1985 Radio Shack catalogue.

Not only that, the Science Fair is based on the older Gakken FX R-165, released in 1981. Building on Gakken's established Denshi Block approach, the FX R-165 was a hybrid electronics kit and microcomputer trainer. The FX series itself following on from the popular EX series of electronic project kits. Nostalgia for these systems eventually compelled Gakken to re-release both the EX 150 electronic kit in 2002 (and a tiny Electronic Block Mini in 2011), as well as their own recreation of the FX R-165 computer block, the GMC-4, in 2009.

Back in the early '80s, the Tandy Corporation, owner of Radio Shack, had noted the novelty of this low-cost educational computer trainer. It seems that Tandy made arrangements with Gakken to bring the core of the FX computer to their own house brand Science Fair. Oddly, despite Science Fair being most famously known for spring-terminal electronic kits, Tandy decided to remove the electronic experimenter aspect of the product and instead focus solely on the microcomputer aspect. The result was the Radio Shack exclusive Science Fair Microcomputer Trainer, a cheaper, cut-down, cardboard facsimile of the Japanese product. The Science Fair version lacked the electronic experimenter focus, normally typical of the brand, and marked the mysterious E3 instruction, responsible for handling external input, as NOT USED.

My own research in to the Science Fair, and later the Gakken R-165, had only developed over the preceding few years. I've long had an interest in extremely basic microprocessors with a view to their application in computer science education. In my teens I constructed Robert Östling's The Brainfuck Computer which implements the unfortunately named Brainfuck programming language. While Brainfuck (or BF as I wish it was more universally called) is an esoteric language, it is fully Turing complete and provides a novel playground for thinking about fundamental computation and minimal CPU instruction sets. Just unfortunate about that name.

I had stumbled across the Science Fair several years earlier while investigating other early educational microcomputer trainers, such as the Heathkit ET-3400 (Motorola 6800), the Micro-Professor MPF-I (Zilog Z80), the Science of Cambridge MK14 (National Semiconductor SC/MP), the Intel SDK-85 (Intel 8085), and the MOS KIM-1 (MOS Technology 6502).

My enquiries about the KIM-1 had lead me to a video by Artifact Electronics in which he demonstrates a small collection of early consumer computing devices. While each of the devices shown has its own charm, as an owner of several Science Fair Electronics kits I was captivated by the, then unknown to me, Science Fair Microcomputer Trainer.

Many early microcomputer trainers expose the full power of their CPU to the user, offering a basic machine code monitor ROM, and just enough peripheral hardware, to allow the user to enter and execute simple programs. Not so for the Science Fair. The Science Fair is aimed at beginners and children, with the box proclaiming For Ages 12 to Adult. Instead of expecting the user to learn the potentially perplexing TMS1000 series instruction set, it instead presents a simplified collection of just 16 opcodes - augmented by a further 16 built-in subroutines - which are interpreted by compact virtual machine embedded in the monitor ROM.

As Michael's YouTube video was then fairly recent, I decided to fire off some additional information about the Science Fair, and its history, to the errant YouTuber. A decision that would end up eating many more hours of my life than I care to admit.

The Science Fair is a fairly well explored machine. Back in March 2015, Sean Riddle had decapped the TMS1100 which powers the trainer. By removing the plastic enclosure of an IC, and revealing the die inside, the contents of mask-programmed ROMs can be read, literally, right from the silicon chip. Despite the destructiveness of the process, decapping is sometimes required to recover the ROM from TMS1000 series microcontrollers. With the right knowledge, electronically reading the ROM is relatively straightforward from early TMS1000 chips. However, later revisions include protection circuits to obfuscate some, or possibly all, of the ROM code. Unfortunately, Sean's attempt to decap the MP1312 MAS^8414 labelled TMS1100 had damaged the die making a purely optical dump impossible.

Fortunately, some time later decle, with his own interest in the Science Fair, and Sean began to communicate about the possibility of securing a copy of the ROM code in a less destructive fashion. Together, and based on the work of Kevin "Kevtris" Horton, they managed to electronically extract a partial ROM. Combining the bits visible on the damaged IC with an obfuscated electronic dump of the code, the two managed to reconstruct a complete copy of the ROM.

Just a few weeks later, in April 2016, decle had proven the validity of the code and developed an emulator for the Science Fair, called Nybl. Nybl is itself a curiosity, and an extremely clever feat of engineering. Nybl emulates the Science Fair on the even more vintage Mattel Intellivision released back in 1979. Despite the limited hardware of the host system, decle notes that his emulator runs at about one third of the speed of a real Science Fair Microcomputer Trainer and takes an average of just 5 CP1610 instructions (the CPU at the heart of the Intellivision) to process a single TMS1100 command.

As it happened, I had not been the only one to contact Michael about his Science Fair video. decle had also reached out regarding his own experience with the Microcomputer Trainer, including information about Nybl and how he had helped to acquire the Science Fair ROM.

While Michael had been documenting a variety of early educational machines, his real passion is the Busch Microtronic 2090. The Microtronic is an early educational computer system created by the Busch Modell company for the West German market and released in 1981. Like the Science Fair, the Microtronic hides the complexities of the TMS1600 microcontroller and, instead, presents the user with a simplified instruction set which is interpreted by the monitor ROM's built in virtual machine. Since 2016 Michael has worked on a number of impressive emulators and recreations of the Microtronic. Most recently, in 2024, his Microtronic extension project the PicoRAM 2090, was confirmed as a Grand Prize winner of the 2023/10 Retro Challenge.

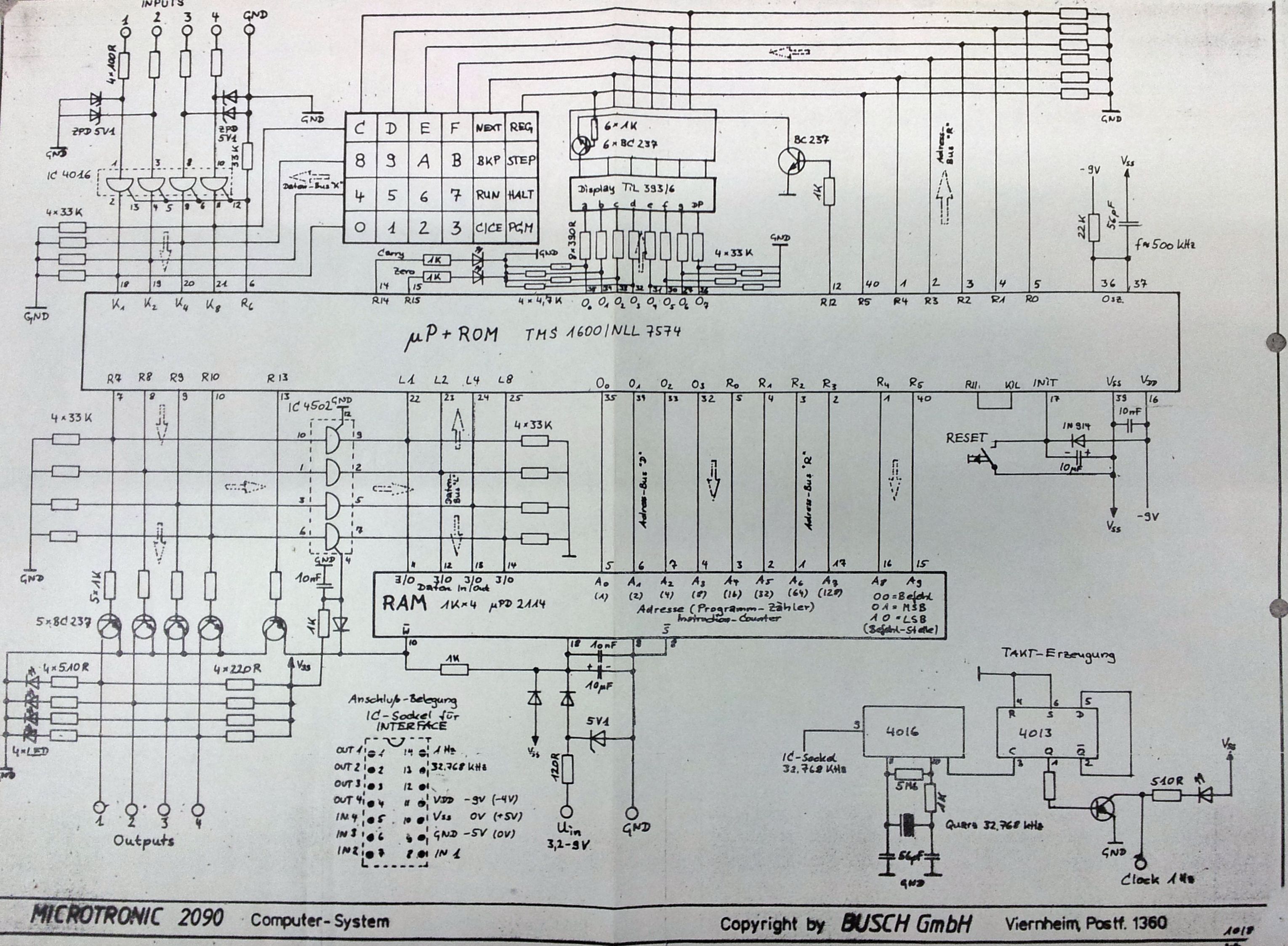

In developing his recreations and add-ons, Michael had sought and archived a huge library of information about the Microtronic in his Github repository. Not only marketing materials, reviews, and the manuals - of which there are several - but also the schematics and other important historical documents. One of the most interesting is the diplomarbeit of one of the key individuals in the development of the Microtronic, and later the owner of Busch, Jörg Vallen. Vallen himself had provided some information, and permissions, to aid Michael's various projects. Despite this encouraging support from Vallen one artefact was missing from Michael's collection: the monitor ROM. The ROM contains the reference implementation of the Microtronic instruction set, crucial to making a truly accurate recreation. Worse still, it seemed that Busch themselves no longer had a copy of the ROM source code.

Yet, there was hope. At least two other companies must have had copies of the ROM. The first was a small firm called MRT. As detailed in Vallen's diplomarbeit, Busch did not develop the ROM code for the Microtronic internally. Instead this task was outsourced to another firm, MRT: Mess- und Regeltechnik. Sadly, it seems, MRT has long since been dissolved and no contact could be made. However, still one final firm must have received copies of the elusive ROM: Texas Instruments.

The TMS1000 series chips store their code in a mask ROM. Once the ROM code for the chip is ready, Texas Instruments would create a photomask that was used during the manufacturing of the wafer to permanently embed the desired program in the fabric of the silicon itself. Unfortunately, despite Michael's efforts, contact with TI was also unfruitful and the ROM was considered lost. What was known, however, was that TI had a process for verifying these chips. A process that allowed the code in the TMS1000 to be accessed and executed. This test mode is further described in a TI patent, and was the very mechanism that Sean, decle, and Kevtris had been exploiting to dump the ROM from other TMS1000 series chips, such as in the Science Fair, almost a decade earlier.

Interestingly, Busch includes a photograph of what appears to be a TMS1600 die in their marketing materials for the Microtronic. Whether or not this is the actual die inside the Microtronic CPU, or a stock photograph from another TMS1000 series device, is unknown. Noting the white body and 64 gold contact pads, it may very well be an example of a rare ROM-less chip. Either way, TI or Busch elected to prevent would-be reverse engineers getting a look at any code that might be present. The blacked-out area in the upper right obscures the location of the mask-programmed ROM.

Possible photograph of a TMS1600 die

The Microtronic uses the more powerful TMS1600 chip. Based on the TMS1100, the TMS1600 features more I/O, a deeper hardware call stack, and more ROM space. While decle, Sean, and Kevtris had managed to dump the ROM from TMS1000 series chips, the exact technique had not been made public. Further, while related to the TMS1100, the specific protocol required for dumping the TMS1600 was unknown to all outside of TI. A fact attested to by the lack of TMS1600 ROMs in the wild. Yet, the idea that it might be possible to extract the ROM code from a TMS1600 was tantalising. It would represent an opportunity to finally realise an authentic recreation of the Busch Microtronic.

It was then, in late February 2024, as Michael pursued the goal of dumping the ROM, that I was fortunate enough to be included in an email exchange between Michael and decle.

In 2016, decle, with the assistance of Sean Riddle, had successfully dumped the ROM of the TMS1100 at the heart of the Science Fair Microcomputer Trainer. Based on the work of Sean Riddle, and by extension Kevin "Kevtris" Horton, decle had used a Parallax Propeller chip to successfully dump 7 of the 8 bits in each byte of the 2,048 byte ROM. decle ported this work to the ubiquitous Arduino platform, and verified that he was able to recreate the dumping process.

The main TMS1000 series are PMOS chips, and nominally run using negative voltages. While some TMS1000 series CPUs run at as much as as -15 V, the TMS1100 in the Science Fair and the TMS1600 in the Microtronic use a more modest -9 V. Negative voltages might seem unusual, but these are only negative relative to the chip ground. Simply swapping the terminals of a normal power supply or battery gives an effective negative voltage. As the TMS1000 series uses positive logic, where a high signal is less negative, this also aligns the signal direction with the other logic.

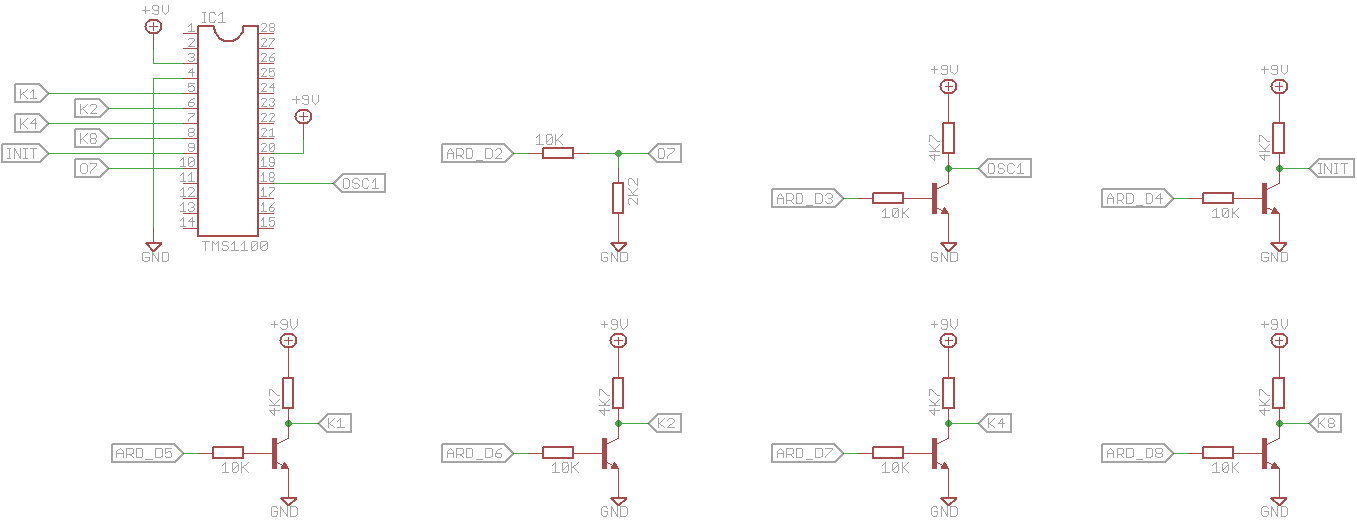

With the CPU voltages sorted, we need to interface with the Arduino. While the TMS1000 chips operate at relative 9 V, the Arduino works at just 5 V. To get the Arduino to talk to a TMS1000 we need to boost the signals. decle achieved this using a simple inverting amplifier, made up of a couple of resistors and an NPN transistor. One amplifier is needed to boost each output. This inversion is handled in the software on the Arduino. Equally, to bring the 9 V output signal to a level appropriate for the Arduino a simple resistor divider is needed to protect the Arduino inputs from excessive voltage. decle provided a simple schematic to illustrate these circuits and where to make the connections on both the Arduino and the TMS1100.

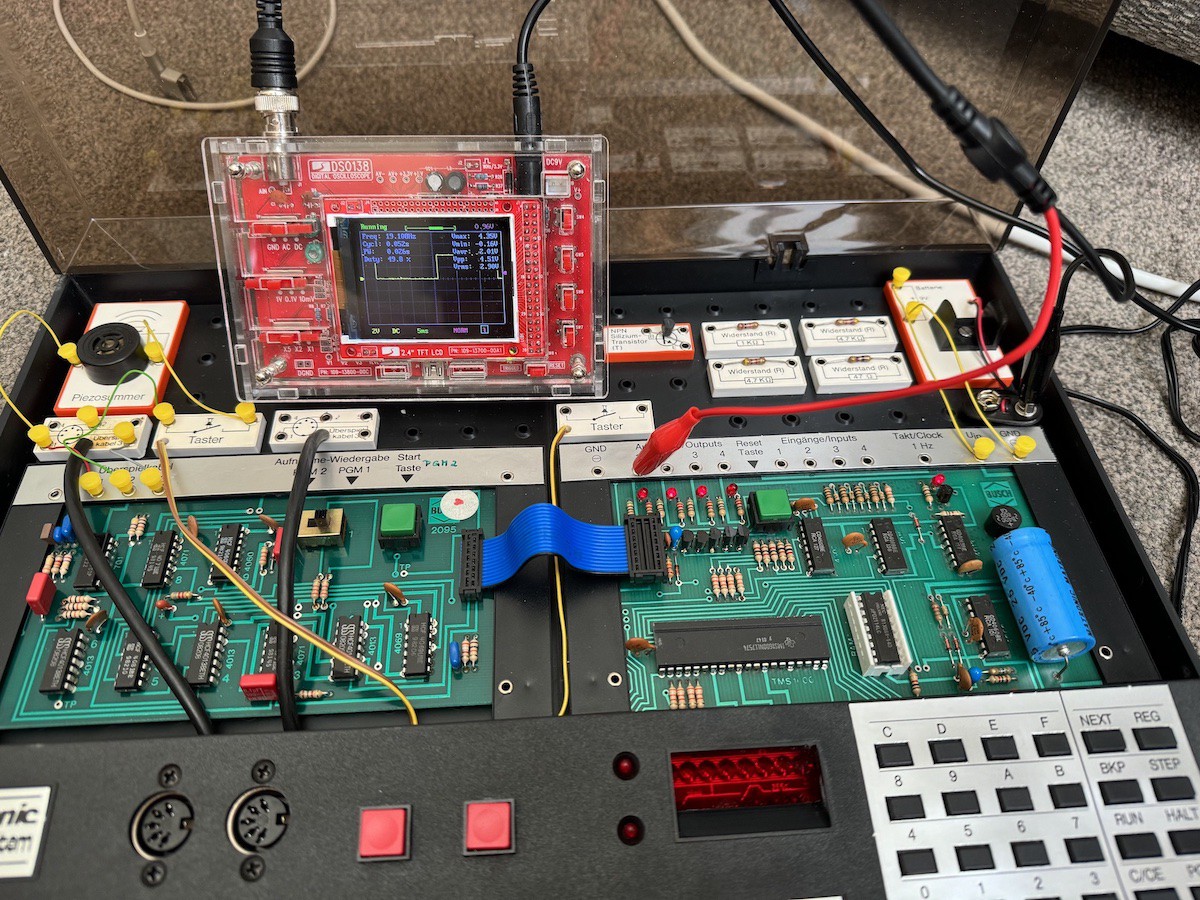

Armed with decle's schematic and the the new Arduino code, both Michael and I were able to successfully recreate the dump procedure on the Science Fair.

The ROM in TMS1000 series chips is logically separated into several levels: chapters, pages, and words. The TMS1000 has just one chapter which holds the entire ROM of 1,024 bytes. Still, due to the limited 6-bit program counter in the TMS1000 series the ROM must be subdivided into 16 pages of 64 8-bit instruction words. More advanced chips, such as the TMS1100 and TMS1600, require multiple chapters, each of 16 pages. Two chapters for the 2,048 byte TMS1100 and four chapters for the 4,096 byte TMS1600.

The precise mechanism to dump the ROM is, in theory, not too complex. The chip is held in reset, the desired program counter is clocked in serially over K1. The page and chapter are transferred in parallel over K2, K4, and, K8. The K2 pin serves double duty, indicating to the chip that the address should be loaded into the program counter, and the value can then be serially clocked out via the O7 pin. The main issue is getting all the timings and sequencing correct. While this gave us 7 of the 8 bits in each byte, I considered that it might be possible to infer the correct value automatically.

All jump instructions, both CALL and BR, have the high-bit set. The test procedure allows both the program counter to be read and a given particular ROM addresses to be executed. Releasing the chip from reset allowed the chip to begin executing the current instruction. If the instruction was a jump, the new program counter would be out of order. Notwithstanding some edge cases, simply executing each byte and checking the program counter would allow most jumps to be validated. Hacking on decle's tool, I was able to apply this approach and conclusively identify the value of 2,007 out of the 2,048 bytes; more than 99% of the bits in the Science Fair ROM. Additionally, it correctly inferred the rest of the bits, matching the known dump.

In my experiments, I noticed that by tweaking the execution timings, some chips - such as the TM1100 in the slightly earlier Gakken Microcomputer R-165 - could be compelled to reveal the entirety of their contents. Even more esoteric and inventive techniques can likely be applied to further interrogate the internals of the chip using carefully crafted test algorithms and techniques, such as those hinted at by the patent and TI's documentation. Combining these techniques it should be possible to extract the user-defined I/O mapping, discussed later, and potentially even reverse engineer customised instructions. Bridges that can be crossed as needed.

The next challenge would be to translate these successes to the TMS1600 at the heart of the Microtronic.

Buoyed by our successes with the TMS1100, Michael attempted to translate what we had learnt to the Microtronic. Directly applying the technique did not, unfortunately, result in a ROM dump. The first step was to try and get the Microtronic to clock along with the Arduino. This process allows the Arduino to control the clock and send addresses to the chip. decle demonstrated the basic technique in his handy video. In addition to correctly wiring the clock, and holding the chip in reset, this requires that the appropriate R pin is held high. Without knowing what the internals of the chip look like the only solution was guesswork.

Unfortunately, unlike the TMS1100 in the Science Fair, the TMS1600 at the heart of the Microtronic is not easily taken out of circuit. While it might be possible to test the chip in circuit, Michael carefully isolated each test pin. After several painstaking attempts, the R8 pin was identified as the likely candidate. Unfortunately, this did not result in a dump.

Michaels next task was to identify the protocol. The exact signals, and sequence, are crucial to getting the TMS1000 series to spill its secrets. First, the ROM on the TMS1600 is twice the size of the TMS1100. To access this extra space required a further bit in the chapter. decle surmised that this bit would be on the K8 pin, which appeared to result in interesting output; though still not the ROM. The final part of the protocol was the timing. The TMS1000 series is tested by loading the desired address in both serially and in parallel, simultaneously. This requires careful sequencing. After testing each of the possible timing sequences, Michael achieved seemingly sensible results. The chip appeared to be responding, but we still were not quite there.

Several further changes to external circuit, the power supply, and the PCB were tested. Eventually, after several days, and much consternation, Michael succeeded. Achieving the ROM dump required removing a support chip, tweaking resistor values, isolating the clock signals, and carefully controlling the voltage and power supply. Michael carefully documented this important breakthrough in his contemporary YouTube video and later Hackaday log. For a more thorough and accurate description, I encourage you to consult his reflections. Interestingly, the dump did not have any protection bit. In the end, after dealing with the minor changes for the extended ROM space and updating the timings, decle's original dumping program seemed to have cracked it. The ROM was finally revealed.

A note on the Gakken FX Computer R-165

The Science Fair Microcomputer Trainer has a well tested ROM. It's been supported in MAME since 0.172, shortly after Sean Riddle and decle successfully recreated the ROM from a damaged decap and a partial dump. Interestingly the artwork in MAME, and the name displayed, is that of the Gakken FX-Micom R-165. This is on the erroneous understanding that the ROM is identical to the Science Fair Microcomputer Trainer. In fact, my own dump of the R-165 has revealed some small, but impactful, differences in the ROM. The revision make two changes. The first change, to key detection, is likely to reduce switch bounce with the morse-style key switches used on the Science Fair. The second change improves the randomisation of, in my opinion, the best of the built-in games: Rat Bashing. The randomisation in the R-165's Whack-a-Mole alike game is ineffectual, and subsequent runs have predictable sequences. This is improved for the Science Fair version of the ROM. For posterity, the differences between the two ROMs is reproduced here in a format suitable for

xxd.00000308: 0e 00000311: 84 000004c2: 65 000004c5: 60 000004cb: 08 000004ce: a7 000004d6: f3 000004d8: a1 000004dd: 76 000004de: 24 000004e1: 25 000004e7: 71 000004eb: 49 000004ec: 0e 000004ef: 2a 000004f0: 96 000004f3: 74 000004f5: 9e 000004f7: 49 000004f9: ab 000004fa: 0f 000004fc: b3 000004fd: 4e 000004fe: 28 00000544: 5f 00000548: 99 00000549: 9b 0000054a: 41 0000054c: be 00000550: 1c 00000551: 0c 00000553: 0b 00000554: 46 00000555: 15 00000559: 08 00000560: b4 00000562: 04 00000564: 0e 00000565: 0b 00000566: 1c 00000568: 21 0000056a: c7 00000572: 0c 00000744: 00 00000749: 00 0000074c: 00 00000753: 00 00000759: 00 00000765: 00 00000766: 00 00000772: 00Assuming the above is saved in a file named

sfmt-to-r165.hexit can be merged into to a copy of the mp1312 ROM file, as used by MAME, to recreate the true Gakken FX Computer R-165 ROM.$ xxd -r sfmt-to-r165.hex mp1312

The nature of the TMS1000 series, with their permanently factory programmed mask ROM combined with their obsolete status, somewhat limits the impetus for maintaining available tooling for these chips. Back in the 1970s, TI offered a variety of tools for development: ROM-less development chips (the TMS1097, TMS1098, and TMS1099); System Evaluator units to aid in debugging (the SE-1 and SE-2, as well as the later SE-1000P, SE-1100P, and SE-1400); a local development system, called AMPL1000, for TMS9900-based mini computers; as well as offering a fully-featured development environment, including simulator, on "nationwide time-sharing systems and at TI computer facilities". Unfortunately, the development chips are rare, the system evaluator hardware obsolete, and the software surely lost to time.

Fortunately, as an early device of its type, the TMS1000 series is a relatively simple processor. The fixed-size 8-bit instruction word means there are only 256 possible bit patterns to decode. Further, as the TM1000 series instruction set is limited to immediate operands, directly encoded into the instruction, the entire standard instruction set can be concisely described on one side of a sheet of regular printer paper.

One caveat to this apparently simple decoding is the program counter, or PC. With most processors the PC is sequential. Not so for the TMS1000 series. Here the PC is a type of shift register and "counts to the next ROM address in a pseudo random sequence". While one source claims that this was to make piracy of the ROM more difficult, this is unlikely. The complete sequence is shown as part of the sample program in the contemporary TMS1000 Series Programmer's Reference Manual, available direct from TI for just $4.95. The more likely explanation lies in the fact that linear feedback shift register counters are known to be more efficient, and occupy significantly less die space, than traditional binary counters when the outputs are required to be synchronised.

Correcting for the unusual PC sequence is not crucial to a naive approach to disassembling the code, but failure to convert the actual location to a logical, sequential, order makes the resulting source indecipherable. Equally important is being able to account for the actual location in jump and call operations, necessitating either the disassembler also translating the target addresses (potentially ill-advised, as we may return to later) or indicating the true in-ROM address of each instruction. Another important note on the PC, which we will undoubtably return to, is its starting location. While the PC itself is set to zero, the page registers, PA and PB, are reset to 0xF on power-up. This means that the program in ROM does not start in the first page, but rather at the beginning of the last page in the first chapter.

Chips in the TMS1000 series have one final trap: the instruction PLA. The instruction PLA, or OPCPLA, is a programmable logic array, specified by the customer and configured during manufacturing of the chip. The OPCPLA allows the basic instruction set of the chip to be redefined. Microprogramming, the process of redefining the OPCPLA, is comprehensively described in Section IX of the Programmers Manual. Fortunately, it seems, changes to the instruction PLA are relatively rare. Firstly, TI's recommended process is to always attempt to use the standard instruction set before resorting to microprogramming. Secondly, over half of the instructions cannot be substantively changed. And, lastly, the SE-1 and SE-2 system evaluators use the standard instruction sets, making custom instruction PLAs more challenging and costly to test.

Given the comprehensive documentation, writing your own disassembler for the TMS1000 series is eminently achievable. Kevtris is known to have used a disassembler coded in BASIC, and similarly decle has written his own Python script. For the less motivated, like myself, perfectly good open-source options are available. My pick is naken_asm by Michael Kohn.

naken_asm was originally designed to provide a simple assembler for another Texas Instruments microcontroller, the TI MSP430, but now supports a wide variety of CPUs. Importantly, it includes support for assembling, and disassembling, code for the TMS1000 series. While the TMS1000 and TMS1100 have different instruction sets, naken_asm supports both. However, the TMS1600 that powers the core of the Microtronic does not presently appear on the list of supported CPUs. Fortunately, the TMS1600 (and TMS1400) standard instruction set is identical to the TMS1100 instruction set - with one notable variation.

To support the extended number of chapters in the more powerful TMS1400 and TMS1600 chips, the COMC instruction was replaced with the TPC instruction. COMC represents "complement chapter buffer", which allows switching between chapters on two-chapter chips. For four chapter chips, such as the TMS1600, the TPC or "transfer page buffer to chapter buffer" instruction allows the programmer to copy the lower two bits of page buffer into the chapter buffer, providing a mechanism to specify any of the four possible chapters.

As an open-source program, you could, of course, hack together an extension for naken_asm to support the TMS1600, or even simply replace the errant code in the TMS1100 decoder. However, the lazy option is simply to translate the generated source using something like sed, e.g.

sed 's/comc/tpc /'The even lazier option is to do nothing. Which is exactly what I do.

naken_asm supports a variety of input formats, but a simple binary format can easily be generated from the plain text dumps we saved as follows.

$ grep "^[0-9A-F]\{2\}" microtronic.txt | xxd -r -p - microtronic.binFirst, we filter out the cruft using grep, insisting that all lines start with at least two hex digits. Then we restore the plain hex codes to binary format using xxd. With any luck we end up with a 4,096 byte file, which can be verified like so.

$ wc -c microtronic.bin

4096 microtronic.binTo actually disassemble the code, naken_asm comes with a complementary utility: naken_util. Documentation is pretty sparse, but the upshot is that you need to use the -disasm flag and specify the CPU type, which for us is the close enough -tms1100. Finally, this is followed by the filename to disassemble. naken_util sends the resulting code to stdout, so you may like to redirect that to a file with the basic output redirection operator: >. If you choose to correct COMC to TPC, by piping through sed, right before this redirect would be the time to do so.

$ naken_util -disasm -tms1100 microtronic.bin > microtronic.lstPeeking inside microtronic.lst we find the following. The lost listing of the Busch Microtronic 2090 ROM.

Linr Addr Opcode Instruction

---- ------ ------ -------------------------------

000 0/0/00: 4f tcy 15

001 0/0/01: 0c rstr

002 0/0/03: 04 dyn

003 0/0/07: 81 br 0x01 (linear_address=0x01)

004 0/0/0f: 0f retn

005 0/0/1f: 28 ldx 0

006 0/0/3f: 4f tcy 15

007 0/0/3e: 7f cla

008 0/0/3d: 27 tam

009 0/0/3b: 04 dyn

00a 0/0/37: bd br 0x3d (linear_address=0x08)

00b 0/0/2f: 0f retn

00c 0/0/1e: 2c ldx 1

00d 0/0/3c: ff call 0x3f (linear_address=0x06)

00e 0/0/39: 2a ldx 2

00f 0/0/33: ff call 0x3f (linear_address=0x06)

...Throughout this document I use naken_asm disassembly format and address notation.

Having secured what looked to be a reasonable listing of the ROM, our first task was to attempt to validate it. Without access to an actual Microtronic to interrogate for clues, my first port of call was the schematic diagram that Michael had made available through his Github repository. There is a lot of useful information here, and we'll refer to it more than once. But, one thing in particular stood out to me. A curious link between R11 and K/L. As we shall see, this provides an important mechanism to control access to the external SRAM, and crucially offers an easily identified entry point for beginning to understanding the ROM.

Much of the general information about the TMS1000 series can be found in the excellent and comprehensive TMS 1000 Series Programmer's Reference Manual. Additional information, including some specific information about the newer and extended TMS1600, can additionally be found in the TMS 1000 Family Microcomputer Data Book.

TMS1000 series chips have three main I/O channels that you must be aware of. Firstly, there is the O channel. O for output. The O channel is driven by a built-in 5-to-8-bit decoder called the Output PLA (Programmable Logic Array), or OPLA. The OPLA controls eight output pins on the device (O0 to O7) and is typically used to allow the chip to map individual values, such as the number 3, to a bit pattern that can represent the relevant digit on a seven-segment display. As the TMS1000 series are four bit processors, the OPLA retrieves the fifth bit from the so-called status latch (SL). This allows the ROM developer to easily define two different outputs for the same nominally 4-bit O register value, one with, and one without, the SL bit set. On most TMS1000 series chips, the output PLA is limited to 20 terms, that is to say that 20 of the 32 possible five-bit values can be uniquely mapped. However, by cleverly combining patters, it is possible to achieve larger numbers of output patterns than a naive mapping approach might imply. On the superior TMS1600, however, this limit is lifted. This allows each of the 32 possible 5-bit values to be mapped to an individual output pattern.

A second output channel is available in the form of the R channel. The R channel is simpler than its O counterpart. Here there is no PLA. Instead, the R channel comprises a series of output pins that can each be individually addressed using the Y register. These are usually used in concert with the O outputs, allowing the device to strobe across a series of seven segment displays, activating each one in turn. Indeed, the Microtronic does just this. Rendering individual numbers via the OPLA to the O pins, and selecting which position on the Texas Instruments TIL 393-6 display to render it via the R0 to R5 output pins. Still, the R channel has another common application, from which it may well get its name: indicating the row in a matrix keyboard layout.

In fact, on the Microtronic the

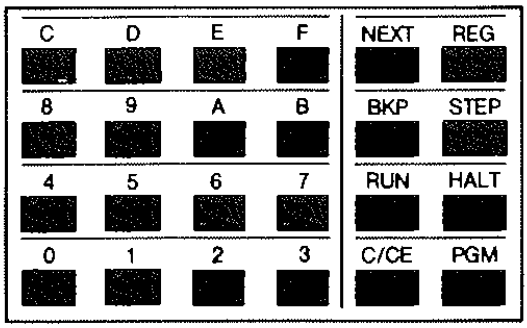

Rpins are connected to the columns of the keyboard. The keyboard panel on several Texas Instruments calculators, the original application for the series, is of the same design as that of the Microtronic but in the portrait orientation.

Most TMS1000 series chips have only four inputs in the form of the K port. These inputs are labelled, for their column value in binary, K1, K2, K4, and K8. Typically, the K port is wired to provide a matrix keyboard, with key switches at the intersection of the individual K inputs and the selected R outputs. Again, this approach is used with the Microtronic. The layout puts a key-switch at each of the 24 intersections between the six R outputs, R0-R5, and the four K inputs, K1-K8. By rapidly enabling and disabling each of the relevant R outputs, strobing them one-by-one, while reading from the K input port, any of the 24 keys can be identified.

The K port on the TMS1600 has one additional trick: a frequency divider on K8. In some applications the data input rate might be too high for the TMS1600 to reasonably respond, but by dividing the input count in hardware the CPU can spend more time doing actual computation. The divider can be configured to directly pass the input state or divide by 2, 10, or 20 at the time of manufacture. However, for devices like the Microtronic such division is unnecessary. In fact, as the K8 line is connected to the keyboard, any divider would make the keyboard unusable.

The garden variety TMS1000 might only have one input port, but the TMS1600 actually has two. It retains the 4-bit K port but adds a new 4-bit input: the L port. The L port offer a secondary set of four input pins, L1, L2, L4, and L8. The L port has a special feature, which again likely led, in part, to its name: it can be latched. Rather than provide only an instantaneous input, the L port can be switched into sense mode by the SE MODE pin. When SE MODE is high, any momentary input will be held until the latch is reset. A reset is caused when SE MODE is brought low. This latching mode allows the TMS1600 to avoid missing external data, as long as it can process the waiting state before the next input. In the schematic for the Microtronic, however, the SE MODE pin is not connected at all. In fact it is not even identified on the main IC. Fortuitously, the TMS1600 has an internal pull-down resistor on the SE MODE pin, ensuring that, by default, the L port simply pass through the momentary state.

While the TMS1600 present two input ports, on two sets of pins, they are, in fact, internally connected to the same 4-bit input bus by means of a multiplexer (mux). To select which input should be read the TMS1600 offers the K/L selector pin. When high, the L port is used. When low, the K port is selected. Like the SE MODE pin, the TMS1600 has an internal pull-down resistor on the K/L pin which defaults the chip to reading the K port. However, as we noted, the Microtronic connects the K/L input pin directly to the R11 output pin, putting this mux under software control.

The Microtronic uses an external 2114 SRAM to store user code. By using a combination of the O (O0-O3) and R (R0-R5) channels of the TMS1600, the Microtronic can address any position in the SRAM. The S pin (sometimes known as the CS pin) on a 2114 must be held low to enable, or chip select, the device. On the Microtronic schematic S is permanently tied to GND. As the Microtronic uses the O and R ports to strobe the keyboard and drive the display, the SRAM is constantly attempting to present the contents of spurious addresses on its output. However, as the SRAM outputs are connected to the L inputs, this spurious data on the L input bus is no bother to the TMS1600. The ROM simply holds R11, and by extension the K/L selector, low which selects the K inputs and ignores the L inputs entirely.

To read the SRAM, the Microtronic ROM must drive K/L high using the R11 output. The mnemonic instruction to set a given R output high is, maybe unsurprisingly, SETR. The R pin is specified by the Y register. As such, we would expect to see the Y register set to 11 by means of the TCY instruction. While it would be possible to interleave these instructions with others, the sequence TCY 11, SETR is a logical starting point. The following multi-line regex searches for this sequence.

tcy 11.*\n.*setrAmazingly, this indicates only one candidate location: 0/9/03. As hypothesised, the ROM sets R11, and thus K/L high. While this enables the L inputs, to actually read the SRAM, the ROM must execute the TKA instruction. TKA loads the data from the input bus into the A register. As we can see, a candidate TKA command follows just five instructions later. So, what do those five instructions do?

Linr Addr Opcode Instruction

---- ------ ------ -------------------------------

242 0/9/03: 4d tcy 11

243 0/9/07: 0d setr

244 0/9/0f: 1d ldp 11

245 0/9/1f: dc call 0x1c (linear_address=0x20)

246 0/9/3f: 17 ldp 14

247 0/9/3e: d9 call 0x19 (linear_address=0x36)

248 0/9/3d: 08 tka

249 0/9/3b: e3 call 0x23 (linear_address=0x23)

24a 0/9/37: 44 tcy 2

24b 0/9/2f: 27 tamAfter setting R11 high at 0/9/07, the ROM calls a subroutine at 0/b/1c. How does this work, and why that address? The chapter buffer register, CB, has not be changed via the TPC (or COMC) instruction, thus we stay in chapter 0; however, we have loaded 11, or 0xB in to the page buffer register, PB, by means of the LDP instruction. Finally, we have a CALL instruction, which provides the last segment of the target address: 0x1C.

Linr Addr Opcode Instruction

---- ------ ------ -------------------------------

2e0 0/b/1c: 2c ldx 1

2e1 0/b/38: 4a tcy 5

2e2 0/b/31: 13 ldp 12

2e3 0/b/23: e1 call 0x21 (linear_address=0x1a)

2e4 0/b/06: 40 tcy 0

2e5 0/b/0d: 7f cla

2e6 0/b/1b: 02 ynea

2e7 0/b/36: 42 tcy 4

2e8 0/b/2d: 21 tma

2e9 0/b/1a: 0a tdo

2ea 0/b/34: 0f retnThis subroutine sets the X register to 1 (using LDX) and the Y register to 5. One of the main uses of the X and Y registers is to provide the index into the internal RAM in the TMS1000 series chips. The ROM then calls another subroutine, at 0/c/21. Unlike the TMS1100, the TMS1600 has a three level stack. Down another level we go.

Linr Addr Opcode Instruction

---- ------ ------ -------------------------------

31a 0/c/21: 21 tma

31b 0/c/02: 4f tcy 15

31c 0/c/05: 27 tam

31d 0/c/0b: 46 tcy 6

31e 0/c/17: 0c rstr

31f 0/c/2e: 04 dyn

320 0/c/1c: 97 br 0x17 (linear_address=0x1e)

321 0/c/38: 4f tcy 15

322 0/c/31: 38 tbit1 0

323 0/c/23: a9 br 0x29 (linear_address=0x2b)

324 0/c/06: 3a tbit1 1

325 0/c/0d: 91 br 0x11 (linear_address=0x2f)

326 0/c/1b: 39 tbit1 2

327 0/c/36: 93 br 0x13 (linear_address=0x33)

328 0/c/2d: 3b tbit1 3

329 0/c/1a: b2 br 0x32 (linear_address=0x37)

32a 0/c/34: 0f retn

32b 0/c/29: 40 tcy 0

32c 0/c/12: 0d setr

32d 0/c/24: 4f tcy 15

32e 0/c/08: 86 br 0x06 (linear_address=0x24)

32f 0/c/11: 48 tcy 1

330 0/c/22: 0d setr

331 0/c/04: 4f tcy 15

332 0/c/09: 9b br 0x1b (linear_address=0x26)

333 0/c/13: 44 tcy 2

334 0/c/26: 0d setr

335 0/c/0c: 4f tcy 15

336 0/c/19: ad br 0x2d (linear_address=0x28)

337 0/c/32: 4c tcy 3

338 0/c/25: 0d setr

339 0/c/0a: b4 br 0x34 (linear_address=0x2a)

33a 0/c/15: 0f retnThis is a thorny bit of code. First, it loads the internal RAM at M(X,Y) into the A register, or accumulator, (TMA). At this point recall that X = 1 and Y = 5; thus A = M(1,5). Next it sets Y = 15 and deposits the A register in its new home using TAM; thus M(1,15) = A, where A = M(1,5), whatever that happens to be.

At 0/c/0b the ROM then sets the Y register to 6, then turns off the R6 output using the RSTR instruction. The code proceeds to decrement the Y register with the DYN instruction. If Y is greater than 0, before the decrement, then the status flag, S, is set to 1 otherwise it is set to 0. The result of this is that the following branch instruction, BR 0x17, causes the RSTR and DYN instructions to turn off all R outputs from R6 down to R0, inclusive.

Consulting the schematic, we can see R6 drives the control lines on a 4016 Quad Bilateral Switch. This IC allows Microtronic to switch between reading external inputs and the keyboard on the K port. It's not clear why the developers felt they needed to turn these inputs off. After all, we are currently reading from the L inputs; K/L is high. Potentially a sequencing optimisation that saves a few bytes elsewhere, but maybe an example of an off-by-one error. The remainder of the loop turns off all of the R outputs that provide addressing to the external SRAM R5 to R0. These are connected to A9 to A4 on the SRAM, respectively. The ROM is preparing to set an address!

When the loop has completed, and the branch at 0/c/1c is not taken, we move forward to 0/c/38. Here, the ROM restores Y = 15, preparing to access the internal RAM. The following series of instructions from 0/c/31 use the TBIT1 instruction to test whether the specified bit at the current memory location, M(1,15) is set to 1. If it is, the S bit is set and the following BR is executed. Each of these branch targets sets the Y register to the matching bit position, uses the SETR instruction to turn on the matching output, restores Y = 15 (required to access the correct memory location), and branches back to continue testing the next bit in the sequence. Having set all the the R outputs R0 to R3, the code finally calls the RETN instruction to to return from this subroutine.

There is a stray RETN at 0/c/15. At first this looks like a clever optimisation. Saving a jump by allowing the subroutine to return from two separate locations. However, on closer inspection we never reach that instruction. Rather than immediately return, instead the code at 0/c/0a branches back to 0/c/34 to actually execute the RETN instruction. A quick search and review of all instances of BR 0x15 in the ROM indicates that this code is never used. Even if it were it would, in almost all possible scenarios, only add more of the same inefficiency.

To summarise, the code so far has copied M(1,5) to M(1,15). It then used the bit pattern in this location to set R0 to R3. In turn, these are connected to address lines A4 to A7 on the external SRAM. Essentially, the ROM has used the value in M(1,5) to set the high bits of the SRAM address.

Our call to 0/c/21 complete, we return whence we came: 0/b/06.

Linr Addr Opcode Instruction

---- ------ ------ -------------------------------

2e4 0/b/06: 40 tcy 0

2e5 0/b/0d: 7f cla

2e6 0/b/1b: 02 ynea

2e7 0/b/36: 42 tcy 4

2e8 0/b/2d: 21 tma

2e9 0/b/1a: 0a tdo

2ea 0/b/34: 0f retnNow, the ROM proceeds to configure the status latch, SL. The value of SL is used by the OPLA in determining the value presented on the O port. First the ROM sets Y = 0, it then it sets A = 0 by using the clear accumulator instruction (CLA), and finally it checks whether Y is not equal to A with YNEA - which of course it is. This has the effect of setting SL = 0.

Next the ROM sets Y = 4, moving our internal RAM pointer to M(1,4). It reads the memory location into A, using TMA. Finally, it outputs that value on the O port using TDO. As discussed in Understanding the hardware, the TDO command combines the value of the SL register with the value written to the O register and maps this to the O outputs using the output PLA, or OPLA. Short of decapping the chip, unequivocally confirming the the mapping is a challenge. Not impossible, but certainly a challenge. However, as we know we are in the middle of setting the address lines on the external SRAM, and O0 to O3 are connected to A0 to A3, it stands to reason that we will be setting a bit pattern representing the binary value stored in M(1,4).

Fortunately, even without a Microtronic to hand, we can verify the significant part of the mapping. Michael Wessel's prize winning PicoRAM 2090 provides a plug-in replacement for the 2114 SRAM on a Busch Microtronic. By checking how the PicoRAM maps the signals it receives to the Pico's internal buffer, we can check for any unexpected mappings. When loading in example program listings from the PicoRAM firmware, the PicoRAM reads bytes into the buffer sequentially. When responding to an address on the address lines, the PicoRAM does not remap the address inputs, but instead fetches those exact bytes from the buffer.

As no remapping of the address is occurring in the PicoRAM, we can conclude that a real Microtronic presents the expected binary bit patterns to the address line. 0b0000 on O3 to O0 (MSB to LSB) for 0, 0b0001 for 1, 0b0010 for 2, and so on. We still cannot confirm the values of O4 to O7 for each of the possible input values, but as these additional O pins do not connect to the SRAM we can surmise they are probably low or that the display is, at least, otherwise disabled. After all, the Microtronic display does not show any visible aberrations during SRAM access.

At this point in proceedings, the ROM has set A0 to A3 using the value in M(1,4) and A4 to A7 using the value in M(1,5). We can conclude that these internal RAM locations are used to store the external SRAM address.

Address 0/b/34 contains a RETN, so, again, we return to the caller: 0/9/3f.

Linr Addr Opcode Instruction

---- ------ ------ -------------------------------

246 0/9/3f: 17 ldp 14

247 0/9/3e: d9 call 0x19 (linear_address=0x36)

248 0/9/3d: 08 tka

249 0/9/3b: e3 call 0x23 (linear_address=0x23)

24a 0/9/37: 44 tcy 2

24b 0/9/2f: 27 tamThe ROM proceeds to prepare for and call 0/e/19. This subroutine is relatively simple, but rather mysterious. For brevity, it is not included here. However, it simply keeps the CPU busy by clearing the A register and looping over an IAC instruction, incrementing the accumulator and using a pair of BR instructions, dependent on the S flag set by the overflow of A, to loop 16 times. It does this twice in 0/e/xx before moving to 0/2/0c, where it loops around once again, and from where it finally returns from this subroutine.

This subroutine idles the CPU for over 150 instructions, each of which take 6 clock cycles. It could be surmised that these wait states were added to allow the external SRAM time to respond to the address change and to present the appropriate data to the L inputs. However, at a nominal 500 kHz, each TMS1600 instruction takes 12,000 nanoseconds. These 150-odd instructions take 1,800,000 nanoseconds, or 1.8 milliseconds. While that might not seem long, the slowest 2114 SRAM offered by TI, in 1979/1980, offered a ta(A) - access time from address - of 450ns and would ready data on the I/O pins in less than a quarter of a single Microtronic clock cycle. Odd indeed.

Back at 0/9/3d transfers the data from the input bus using TKA. TKA nominally stands for transfer K-inputs to accumulator, however, as the ROM is currently holding K/L high the instruction reads from the L inputs. Finally, the A register holds the first 4 bits of data from the SRAM!

Before storing the data in the internal memory, using the TAM instruction, the ROM calls yet another subroutine: 0/9/23.

Linr Addr Opcode Instruction

---- ------ ------ -------------------------------

263 0/9/23: 4f tcy 15

264 0/9/06: 27 tam

265 0/9/0d: 38 tbit1 0

266 0/9/1b: 93 br 0x13 (linear_address=0x33)

267 0/9/36: 30 sbit 0

268 0/9/2d: 3a tbit1 1

269 0/9/1a: 8c br 0x0c (linear_address=0x35)

26a 0/9/34: 32 sbit 1

26b 0/9/29: 39 tbit1 2

26c 0/9/12: b2 br 0x32 (linear_address=0x37)

26d 0/9/24: 31 sbit 2

26e 0/9/08: 3b tbit1 3

26f 0/9/11: 8a br 0x0a (linear_address=0x39)

270 0/9/22: 33 sbit 3

271 0/9/04: 21 tma

272 0/9/09: 0f retn

273 0/9/13: 34 rbit 0

274 0/9/26: ad br 0x2d (linear_address=0x28)

275 0/9/0c: 36 rbit 1

276 0/9/19: a9 br 0x29 (linear_address=0x2b)

277 0/9/32: 35 rbit 2

278 0/9/25: 88 br 0x08 (linear_address=0x2e)

279 0/9/0a: 37 rbit 3

27a 0/9/15: 84 br 0x04 (linear_address=0x31)Another substantial subroutine. So, what does it do? First it loads Y = 15, updating our memory pointer to M(1,15), and then stores the contents A register in that location: M(1,15) = A. The ROM then proceeds to do a series of tests on each bit, similar to what we saw before as it used the bit pattern from part of the address to set the R outputs. Just like before, when TBIT1 sets the S status flag to 1, the code branches to the respective segment of the code; if not the branch that follows is skipped.

For example, if the bit in position 0 was 1 then the code branches to 0/9/13. This instruction resets, or clears, the bit using RBIT. If the bit in position 0 had already been 0, the S flag is set to 0, the branch is skipped, and instead the code sets the bit with SBIT. If flips the bit! The code proceeds to step through all four bit positions, flipping each in turn. Finally, it copies the result from the internal memory, back into the A register and returns.

To summarise, this subroutine temporarily stores the accumulator, A, in M(X,15); inverts each individual bit; copies the result into A; and, finally, returns. A 4-bit complement operation. But why?

While some external memories offer inverted output, such as the 74S289, the 2114 SRAM is not one of them. Instead we have to blame the 4502 Strobed Hex Inverter/Buffer. The Microtronic uses R7 to R10 to indicate the data that should be written to the RAM. However, these pins are also used to provide the user-controlled outputs. As the data pins on the 2114 SRAM are bidirectional, these pins must also be connected to the L inputs. Without some mechanism to block these signals the Microtronic would have to disable the user-outputs every time it wanted to access the RAM. Such constant switching, as would be needed while the user-program was running, would constantly interrupt the user-specified output signals. The 4502 provides a mechanism to prevent the user-specified outputs interfering with the L inputs, without turning those output signals off.

What is special about the 4502 is that it offers three-state outputs (also called tri-state or 3-state outputs). That is to say, when DISABLE, on pin 4, is pulled high the chip presents a high-impedance state on its outputs preventing the presence of the device causing interference with the other signals on the so-called L bus. As indicated in the schematic, by default, this pin is held high by a pull-up resistor. When the Microtronic wishes to write to the SRAM it simply pulls R13 high, which pulls the W pin on the 2114 SRAM low via a transistor, indicating it should write the incoming data to the indicated address on the A0 to A9 inputs. The same signal, via the transistor, pulls the DISABLE pin low on the 4502, enabling the chip. This allows the signals from R7 to R10 to pass from the input pins, through the device, and on to the L bus. Crucially, when the 4502 passes the data through, it inverts the signals. This results in the complement of the intended data being stored in the SRAM.

Briefly, it's worth noting that there is a small error, here, in the the schematic. The

R13transistor is backwards. Not on an actual Microtronic, as Michael Wessel has verified, but in the diagram. On a real device, all of the emitters in that group of transistors are connected together and it is the collector that pulls both pin 4 of the 4502 and theWline of the 2144 SRAM low.

While the 4052 does the job, inverting the data makes a lot of work for the TMS1600 to recover the intended value from the inverted bits. As an alternative, non-inverting buffers, such as the 4053, could have been used. Still, assuming that the hardware had been set, and no other chip could be used, this approach is painfully inefficient. If the ROM is recovering 0xF it takes 16 instructions to set all of the bits. Worse, if the ROM has has to reset every bit, to recover 0x0, it would take 20 instructions.

Instead of implementing the complement bit-by-bit, the TMS1600 offers the CPAIZ instruction. CPAIZ is complement accumulator and increment (two's complement accumulator). While this instruction is not exactly what is needed, after all it adds one to the value, this is easily resolved. The handy DAN operation subtracts one from the accumulator, turning the two's complement back into a regular complement. Curiously, as seen in the documentation, the DAN instruction is equivalent to A + 14 + 1 → A. As it happens, the TMS1600 instruction set does not really support subtraction; instead it handles this as an addition and overflows the maximum value.

Ignoring the copying of the A register in to M(1,15) - as it's only used as a temporary location to allow the bit manipulation to occur - this entire subroutine could be replaced by two instructions. Or, if the authors really need the complement to remain a separate subroutine, three. e.g.

Linr Addr Opcode Instruction

---- ------ ------ -------------------------------

0/9/23: 3d cpaiz

0/9/06: 77 dan

0/9/0d: 0f retnNevertheless, once the data recovery phase is complete, the ROM returns from the subroutine call and the code resumes at 0/9/37.

Linr Addr Opcode Instruction

---- ------ ------ -------------------------------

24a 0/9/37: 44 tcy 2

24b 0/9/2f: 27 tamHere we see the final two actions needed to complete this SRAM read. These ROM code sets Y = 2, and thus our memory pointer to M(1,2). Finally it copies the freshly inverted A register, representing the word read in from the SRAM, into this space in the TMS1600's internal memory.

The ROM goes on to read two more words before returning back to the caller. First it enables R5, before doing another SRAM read and placing the result in M(1,1). It then proceeds to switch R5 off again, switch on R4, and read another word from the SRAM before storing it in M(1,0). Finally, it turns off R11 disabling the L inputs, and indicating the end of the RAM access, before executing the RETN instruction.

Why does the ROM do two further reads? Again, we refer to the schematic. Here we see that R4 and R5 are connected to A8 and A9 on the SRAM respectively. These signals are combined with the base address to provide access to each 4-bit chunk of the Microtronic's user-facing 12-bit instruction set. The schematic notes that when A8 and A9 are 00 (both low) this is mapped to the befehl: the command. When just A9 is high, this is mapped to the MSB: the most significant bits of the operand. Finally, when just A8 is high, this is mapped to the LSB: the least significant bits of the operand.

Interestingly, the Microtronic never uses the final combination where both A8 and A9 are high. A quarter of the SRAM on the Microtronic is simply never used.

Our exploration of the memory access routine has revealed some useful information about the way the Microtronic handles memory, both external and internal.

We know that the pointer to the base address of the current instruction in SRAM is at M(1,5) and M(1,4). The ROM then uses this to address the SRAM and read thee 4-bit words, representing the Microtronic's 12-bit instruction word, into M(1,2), M(1,1) and M(1,0).

| Location | Content |

|---|---|

M(1,5) |

pointer to SRAM address (high bits) |

M(1,4) |

pointer to SRAM address (low bits) |

M(1,2) |

instruction buffer (command) |

M(1,1) |

instruction buffer (most significant bits) |

M(1,0) |

instruction buffer (least significant bits) |

The Microtronic comes with a few built in programs, but one of the more interesting is the nim game. Nim is detailed on page 7 of the Microtronic manual. The purpose of the game is remove match sticks from a pile, but not to be the person who takes the last one. Mathematically the game is interesting in itself, and the Microtronic exploits the mathematical theory to, very frequently, win the game. However, for the purposes of exploring of the ROM, that's not what is makes the program notable. While the game naturally exists in the ROM, when recalled it is copied into the SRAM and executed as would be any other user-defined Microtronic program.

The full code for NIM, 69 12-bit words, is as follows:

F08 FE0 F41 FF2 FF1 FF4 045 046

516 FF4 854 D19 904 E19 B3F F03

0D1 0E2 911 E15 C1A 902 D1A 1F0

FE0 F00 F02 064 10C 714 B3F 11A

10B C24 46A FBB 8AD E27 C29 8BE

E2F 51C E2C C22 914 E2F C1C F03

0D1 0E2 F41 902 D09 911 E38 C09

1E2 1E3 1F5 FE5 105 FE5 C3A 01D

02E F04 64D FCE F07To recall the program from ROM, the user presses HALT, PGM, 7. At which point the Microtronic begins copying the code into the SRAM.

To write to the SRAM the Microtronic must drive R13 high. Just as before we can search for this with a simple regular expression.

tcy 13.*\n.*setrAgain, we find just one candidate block of code.

Linr Addr Opcode Instruction

---- ------ ------ -------------------------------

314 0/c/35: 4b tcy 13

315 0/c/2b: 0d setr

316 0/c/16: 4b tcy 13

317 0/c/2c: 4b tcy 13

318 0/c/18: 0c rstr

319 0/c/30: 0f retnHere, we see the R13 line being briefly driven high, before being set low again. This writes the current data on the data pins to the address specified by the address pins. After this, the subroutine returns. There is an obvious unnecessary duplication of the TCY command at 0/c/2c. Equally, unless this stub of code is being reused elsewhere, it might have been possible to remove the TCY at 0/c/16 as well; after all, Y is already set correctly. Like with the strange delays in the read subroutine, it is possible that these seemingly nonsensical operations are simply for delay; but again, even a single clock pulse should provide ample time for the write to complete. I am wont to wonder if these two instructions, at one point, read LDP 14, CALL 0x19. Like in the read routine, adding a substantial and unnecessary pause to proceedings.

Unlike with the read subroutine, where the interesting code followed our sentinel snippet, when writing to the SRAM all the configuration must be done first. As such, we must work our way back through the ROM code. The three lines immediately preceding the write request look like so.

Linr Addr Opcode Instruction

---- ------ ------ -------------------------------

311 0/c/0e: 21 tma

312 0/c/1d: 17 ldp 14

313 0/c/3a: c3 call 0x03 (linear_address=0x02)Working backwards, the call at 0/c/3a is very unlikely to be branched into from elsewhere. Code that wishes to CALL 0x03 can do so directly, so this instruction is not interesting it its own right. Likewise for the LDP at 0/c/1d. While it could, potentially, save a byte to trampoline from here to 0/e/03, it doesn't make much sense to do so. Just to be sure, though, we can quickly check the code with a cryptic regex.

(ldp 12(.*\n){1,2}|0/c/).*(call|br) 0x(3a|1d)For the uninitiated, we are asking the matcher to find either an LDP instruction which is setting the page buffer to C, or for the code to already be in chapter 0 and page C. Where the page buffer is set, we allow for any extra cruft on that line, including the new line, and up to one further intermediate line (as described below). Finally, the matcher is then told to ignore any remaining junk on the line and look for a CALL or BR to either 0x3A or 0x1D. No results.

It's worth noting that this is not a completely exhaustive search. We could allow for more intermediate lines to account for more complicated sequences, e.g. interleaving configuration and test to prepare for a conditional jump. But as we allow more potentially unrelated content to match, even if we increase the complexity of the pattern to try and minimise issues, we risk getting larger and larger numbers of false positives. For our purposes, this pattern is good enough.

Taking a peek at what that subroutine at 0/e/03 does, we find that it takes the contents of the accumulator, A, and sets outputs R7, R8, R9, and R10 using a similar technique we saw earlier to set the relevant R outputs used for the SRAM address. As we can see on the schematic, R7 to R10 are connected to the user outputs and, maybe more crucially, to the 4502 which can selectively gate them into the SRAM when it is time to write the data.

The next line, upwards, 0/c/0e looks promising. This line reads the current memory address into the A register. Knowing that the next line will call a subroutine that will present that value on the outputs, 0/c/0e is certainly a candidate target address. Another (almost identical) regex to the rescue.

(ldp 12(.*\n){1,2}|0/c/).*(call|br) 0x0eThis time we find five candidate callers. Two of these callers are just a few lines above, likely reusing this block of code to output the other two of the three 4-bit words that make up the Microtronic's 12-bit instructions. Curiously, however, there are three more callers coming from in from 3/f/xx; the first at 3/f/06.

Linr Addr Opcode Instruction

---- ------ ------ -------------------------------

fe0 3/f/1c: 44 tcy 2

fe1 3/f/38: 10 ldp 0

fe2 3/f/31: 0b comc

fe3 3/f/23: 13 ldp 12

fe4 3/f/06: ce call 0x0e (linear_address=0x11)Going backwards through the code we see that the page buffer is being set to C, using LDP, and the chapter buffer to 0 by means of the TPC instruction (mentally translated from the errant COMC). The instruction before this, at 3/f/1c, changes Y = 2. This is interesting. As we've identified, the subroutine starting at 0/c/0e loads the memory location specified by X and Y into the A register and processes it for presentation to the SRAM. It is, in essence, a data output subroutine. So, what data is being stored in memory location Y?

Linr Addr Opcode Instruction

---- ------ ------ -------------------------------

fd5 3/f/2b: 40 tcy 0

fd6 3/f/16: 61 tcmiy 8

fd7 3/f/2c: 60 tcmiy 0

fd8 3/f/18: 6f tcmiy 15

fd9 3/f/30: 60 tcmiy 0

fda 3/f/21: 60 tcmiy 0

fdb 3/f/02: 60 tcmiy 0

fdc 3/f/05: 10 ldp 0

fdd 3/f/0b: 0b comc

fde 3/f/17: 1d ldp 11

fdf 3/f/2e: dc call 0x1c (linear_address=0x20)Scrolling up we look to see what is setting the memory at Y = 2. The call to 0/b/1c, set up by 3/f/05 onwards, looks familiar. That subroutine is used to set the SRAM address. We considered it in detail when investigating SRAM reads. Crucial, but it doesn't set the contents of the internal memory at M(x,2).

Stepping back further, we see a series of TCMIY instructions. These instructions store a value at the current internal memory location then increment the Y pointer. At 3/f/2b we are shown the base address for these insertions into the internal RAM, 0.

A summary of the result of these writes, to the internal RAM, is as follows.

| X | Y | Value |

|---|---|---|

| ? | 0 | 8 |

| ? | 1 | 0 |

| ? | 2 | F |

| ? | 3 | 0 |

| ? | 4 | 0 |

| ? | 5 | 0 |

Recall, the first value of interest is at Y = 2. When we consider the other candidate calls to our so-called data output subroutine at 0/c/0e we see that they set Y = 1 before the next call and Y = 0 before the final call. Thus they output, in order, F08 to the SRAM. Sound familiar? F08 is the first 12-bit word in our nim game.

We still don't know what X is. Though we might have an inkling, it would be nice to check. This requires working backwards. Immediately preceding the code that writes to internal RAM is an unconditional branch. So, what branches or calls into 3/f/2b?

(ldp 15(.*\n){1,2}|3/f/).*(call|br) 0x2bA single candidate. One that sets X = 1. The question marks in the previous table would be 1.

Linr Addr Opcode Instruction

---- ------ ------ -------------------------------

e3d 3/8/28: 2c ldx 1

e3e 3/8/10: 1f ldp 15

e3f 3/8/20: ab br 0x2b (linear_address=0x15)This aligns nicely with our existing understanding of the Microtronic memory map. M(1,2), M(1,1), M(1,0) hold the current instruction and M(1,5), M(1,4) tell us where it can (or should) be found SRAM.

Having, very probably, found the first word of the nim game can we find the rest? To do so we must look forward. After our final data output subroutine call, the CPU resumes at 3/f/0c.

Linr Addr Opcode Instruction

---- ------ ------ -------------------------------

ff5 3/f/0c: 40 tcy 0

ff6 3/f/19: 0f retn

ff7 3/f/32: 15 ldp 10

ff8 3/f/25: b7 br 0x37 (linear_address=0x0a)

First the code sets Y = 0 and then we find a RETN. The question is, return to where? This can be a problem of dipping into the code as we have done. We have no idea of what the call stack might look like at this point. However, this is where a little luck and intuition might just work out for us. As it happens, when the hardware call stack is empty an errant return is essentially ignored. In essence, if our call stack is empty then this instructions is a no-op. One interesting application of this feature is that it can be used to allow the same segment of code to be used in two different ways. One way when the call stack is empty and another when there is somewhere to actually return to.

Interestingly what follows this RETN is an unconditional branch to 3/a/37. This could be a form of trampoline, allowing another jump in this same page to redirect to the new location. It could, also, be used from another page, but there would be no real benefit to doing so. Nevertheless, both scenarios are easily checked.

(ldp 15(.*\n){1,2}|3/f/).*(call|br) 0x32No results. So, maybe we do have a tricksy bit of code reuse on our hands. Let's assume so. In which case, let's look at the target location of this branch to 3/a/37

Linr Addr Opcode Instruction

---- ------ ------ -------------------------------

e8a 3/a/37: 60 tcmiy 0

e8b 3/a/2f: 67 tcmiy 14

e8c 3/a/1e: 6f tcmiy 15

e8d 3/a/3c: c0 call 0x00 (linear_address=0x00)

e8e 3/a/39: 68 tcmiy 1

e8f 3/a/33: 62 tcmiy 4

e90 3/a/27: 6f tcmiy 15

e91 3/a/0e: c0 call 0x00 (linear_address=0x00)

e92 3/a/1d: 64 tcmiy 2

e93 3/a/3a: 6f tcmiy 15

e94 3/a/35: 6f tcmiy 15

e95 3/a/2b: c0 call 0x00 (linear_address=0x00)

...Having previously set Y = 0 the code now begins populating M(1,0), M(1,1), and M(1,2) with data. This time FE0, the second byte of nim! Right where we expect it to be stashed in the internal RAM, ready for output. At 3/a/39 we find the code to populate this cache with the third nim byte, F41; at 3/a/1d the fourth, FF2; and so on.

But what about the numerous CALL 0x00 instructions? Without an explicit chapter and page, these call the code at 3/a/00. For brevity, this block of code is not reproduced here. However, to summarise, the code updates the SRAM pointer, in M(1,4) and M(1,5), before branching back to the code we saw earlier, at 3/f/05, that sets the SRAM address and writes out the three 4-bit values. This time, as the CALL to 0x00 has populated the stack, our seemingly superfluous RETN at 3/f/19 takes effect. This then drops the CPU back at the correct place in the sequence ready to transfer the next word of instructions from the ROM, into RAM, and eventually into the SRAM. I leave the detailed review of this sequence as an exercise for the reader.

By finding nim, it seems we have a basic understanding of how the Microtronic reads and writes the SRAM. Maybe more importantly, we have confirmed that the logic is sound and thus we probably have a sensible dump of the ROM.

While all this analysis is fun, it's probably time to see what else can be done with the Microtronic ROM.

Beware of bugs in the above code; I have only proved it correct, not tried it. -- Donald Knuth

Not having actually executed the code so far, we can only be so confident about the validity of our ROM. The acid test, as it were, would be to run the ROM on real Microtronic hardware and see what it does.

Unfortunately, as the TMS1000 series have a mask programmed ROM, we can't practically execute the code on a real TMS1600. ROM-less evaluation chips were made available; however, they are exceptionally rare. While the TMS1099 (a ROM-less TMS1000) has a WikiChip page, and the TMS1098 (a ROM-less TMS1100) even has a YouTube demonstration, we would need a TMS1097 to support the 4,096 byte ROM as used on the Microtronic. Outside of official Texas Instruments documentation, specifically the datasheet and price list, references to the TMS1097 in the wild seem practically non-existent.

We could, of course, simulate the TMS1600 entirely in software, but the Microtronic is more than just its software. The TMS1600 is the conductor of a cacophony of hardware. It controls, or reacts to, a variety of other physical devices: the SRAM, display, keyboard, and more.

Much of the hardware that makes up the Microtronic is still in production to this day. In addition to the basic parts-bin passives, resistors and capacitors in various values, all of the following can still be purchased new and in quantity.

More troubling, obsolete or out of production, parts include the following.

While considered obsolete, 2114 SRAMs are readily available; even in quantity. There are companies, such as Rochester Electronics, that specialise in this kind of medium-volume vintage parts. Alternatively, newer, larger, SRAMs could also easily be pressed into service by simply tying unused inputs up or down, as needed, and using only part of their capacity; after all, this is what Busch did with original SRAM in the Microtronic anyway.

The TIL393 display is now sadly out of production. Until recently, a few suppliers seemed to have new old stock available but these displays are increasingly hard to find. Still, it is relatively easy to recreate such a display with modern 7-segment LEDs. Individual units can be used or, to minimise parts, two 3-digit displays could easily be paralleled. Michael Wessel has recently demonstrated such a 7-segment based display attached to a real Microtronic.

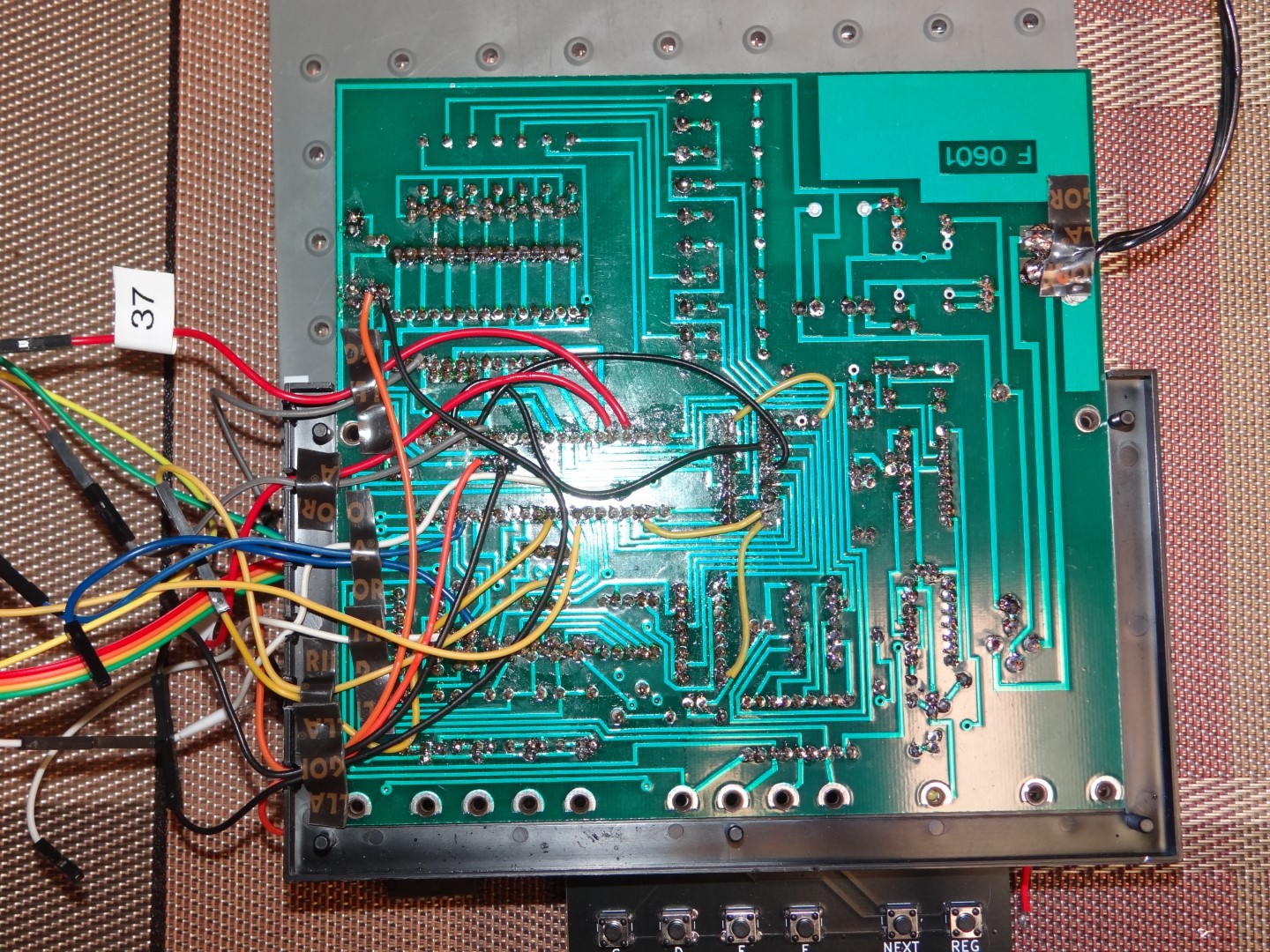

While reputable suppliers are available - Mouser was linked here only as DigiKey had no in stock BC237 transistors at the time of writing - I, in fact, purchased all the active components via AliExpress. Total cost of approximately £8, delivered; though I'm ignoring all the other tat I added to the orders that I probably didn't need to buy. For the obsolete 2114 SRAM and a knock-off, but vintage, TIL393 display, I turned to eBay. About another £6. Your milage may vary. I also spent a few pounds on various extra resistors, capacitors, etc. I am also ignoring the cost of wires, breadboards, and LEDs that I already had. All told, you could probably argue assembling my breadboard Microtronic cost me somewhere between £20 and £50 in parts.

The most crucial part, however, is the TMS1600 compatible microcontroller. While it might not be possible to source a TMS1097, today there are an array of modern microcontrollers available that can easily be programmed to carry out a wide variety of tasks. One such device is the humble ATmega328P, the processor at the core of the popular Arduino Uno R3. I could have, and maybe should have, chosen another platform. However, these chips are cheap, easy to program, readily available, and I happened to have a bunch to hand.

Should you, too, like to build your own Microtronic, a few comments on the schematic.

- As previously noted, the transistor connected to

R13is backwards. All of the emitters in that group of transistors should connected together. The collector should connect to both pin 4 of the 4502 and theWline of the 2144 SRAM.- The 4060 in the lower right is incorrectly labelled as a 4016. This use of a 4060 can clearly be seen on the front cover of the manual and in other photographs of the PCB.

- Pin 12 on the 4060 must be pulled low (to

GND). If left floating, as implied by the schematic, the counter will randomly reset.- It is pin 3 on the 4060,

Q14, that is connected to pin 3 on the 4013. This label is missing on the schematic.- Power and

GNDare not specified for any of the ICs (except the TMS1600). All of the 5 V chips should have their source pins connected toVSS, +5 V, and andGNDset toGND. Note the helpful annotations converting between the two voltage potentials indicated on the pins 9, 10, and 11 of the INTERFACE socket.- The pin numbers for

R0toR5are incorrectly labeled.R0is pin 40 on the TMS1600, andR1toR5are on pins 1 to 5 respectively as shown in the data book. Connections are made with respect to their designators, not their pins; e.g. A9 on the SRAM (pin 15) should be connected to R5 on the TMS1600 (pin 5).

R0toR5multiplex the TIL393 from right to left (i.e.R0is the right-most digit).To reduce the number of components, it may be possible to replace the block of transistors, above the TIL393-6 display, with the common ULN2003. In fact a prototype Microtronic clearly uses a ULN2004 (a minor variant) for this function, which likely explains why these transistors are shown as a block rather than individual components.

As everything other than the TMS1600 runs at 5 V, including the ATmega328P, I simply run the whole system off of the same 5 V rails. To create a true drop-in substitute CPU you would need to add an extra on-board power supply to adjust the input voltage and include additional logic shifting to faithfully recreate the inputs and outputs of the Microtronic's TMS1600. Much of the Microtronic's circuit complexity is dealing with the mismatched logic between the TMS1600 and the other ICs. For a prototype breadboard recreation, powering everything from a -9 V supply only to convert it back again seemed unnecessary and misguided.

Hardware done, but we'll still need an emulator capable of executing the ROM.

To properly test the Microtronic ROM, we need an emulator for the TMS1000 series. Surprisingly, there are a few different ones available. One of the more unusual is a TMS1000 emulator in Minecraft. This zany creation was made back in 2011, by WarlockD, and demonstrated in their YouTube video.

A more practical emulator is mvem, an emulator from early 2014 by Paul Robson for the Microvision. The Microvision was the first hand-held games console to use interchangeable cartridges. The CPU was part of the cartridge and could be either a Texas Instruments TMS1100 or Intel 8021 depending on the game. mvem can run on Windows and does appear to have been ported to the Arduino. Sean Riddle then ported the mvem code to a PIC18F46K22 clocked at 64 MHz, eventually managing to achieve timing accurate emulation. While MHz aren't everything, the ATmega328P tops out at less than a third of that, which doesn't bode well for performance.

MAME, an emulator for classic arcade systems, emulates innumerable games and devices. It has supported parts of the TMS1000 series since at least 2009, with significant updates around 2016. However, MAME is targeted at much more powerful host devices and the TMS1000 support is part of the larger MAME infrastructure which might not lend itself to easy isolation. Like MAME, hotkeysoft has developed a collection of emulators, including one for the TMS1000 series. The hotkeysoft emulators are designed to be portable, and were ported to the ATmega328P in late 2019. However, the hotkeysoft emulators are reasonably tightly coupled to their target ROMs and the ports, at least, don't provide precision timing.

These emulators all have their charm, and there is nothing fundamentally wrong with their approaches. They all suit their need and niche. My planned use case was, however, slightly different. To provide something I could drop into the existing Microtronic schematic, I'd need it not just to run the ROM but also to act externally like a TMS1000. As such, the emulator would need to emulate a naked TMS1000 series chip, rather than tie it to a specific application. This focus on being a drop-in-replacement has the benefit that it could, in theory, emulate a variety of TMS1000 series chips, in a variety of real-world applications, just by swapping out the ROM. Many of the emulators identified do indeed emulate a variety of TMS1000 series chips, and it is certainly a potentially useful feature. In fact, the first ROM I wanted to run was not actually that of the Microtronic. Rather, I intended to run the well-tested ROM from the Science Fair Microcomputer Trainer.

The Science Fair Microcomputer Trainer is a pretty basic device. Far simpler than the Microtronic. A chunk of the schematic for the Science Fair is literally printed on its cardboard frame. As the final wiring must be completed by the end user, the remainder is in the manual. With the exception of the oscillator circuit and the one-transistor amplifier for the speaker, there is little more to it than a few morse-style key switches and a handful of LEDs with current limiting resistors.

The Science Fair uses an 400 kHz ceramic resonator to clock the CPU. While ceramic resonators represented a cost saving over more accurate crystals, the speed of a TMS1000 series chip can actually be configured using a simple RC circuit. So why does the cost-reduced Science Fair use a resonator at all? Sound. The Science Fair generates audio tones using nothing more than carefully timed loops to pulse the speaker. For simple beeps, bleeps, and bloops that might not matter. Musical tones require pretty accurate timing or the tune will sound a little off key.

Additionally, while the TMS1600 and TMS1100 are very closely related, the TMS1100 is the simpler of the two. Offering less I/O, a smaller ROM, and a simpler call stack. The instruction set is also comprehensively described in the programmers manual.

While, as we now know, emulators exist for the TMS1100, my application presupposed two main features: to emulate the more-or-less naked chip, and to provide instruction-accurate timing. For an ATmega328P, together, these two requirements present quite the challenge.

The first is challenge is the I/O. The TMS1100 has 4 inputs and 19 outputs, requiring a total of 23 pins. Fortunately the ATmega328P has precisely 23 I/O pins. Unfortunately one of those is actually the reset pin. While we don't really need the reset pin, once configured as an I/O pin the device cannot be reprogrammed without the use of a high-voltage programmer; fixable but a faff that would slow development and limit the appeal.

To avoid having to use the reset pin as an input, I use a nasty hack which abuses the AREF pin as the input for K8. When checking for K8 the key reading routine actually switches either ADC0 or ADC1 to input mode and assumes that pin is low. If AREF is high, due to a key being pressed, the ADC will read low; thus K8 is 1. If AREF is low, helped by a pull-down resistor, then the ADC will be at the same potential as AREF and the ADC will read high; indicating that K8 is 0. As indicated, this does require that, during the test, one of those ADCs is not itself being used as an output. To ensure this will be true, these pins are used as R2 and R3 respectively (labelled RE and RF on the Science Fair itself). The Science Fair ROM uses these lines to strobe across the keyboard matrix, one column at a time. Therefore we know that at no time will both of these lines be in use and held high simultaneously. Using the ADC does introduce a small delay in the routine, but by carefully structuring the code we can minimises the additional overhead of this technique.

The next challenge is timing. Again, while we can eke out just enough I/O from the chip, we can only do so if we give up the use of an external oscillator. Due to the popularity of the Arduino Uno, the ATmega328P is typically run at 16 MHz using an external crystal. Unfortunately, this requires sacrificing two I/O pins. The ATmega328P can run using its internal oscillator, but it is limited to just 8 MHz. A far cry from the 20 MHz top speed we might have otherwise taken advantage of.